Exploring Common Types of Fittings: A Comprehensive Guide

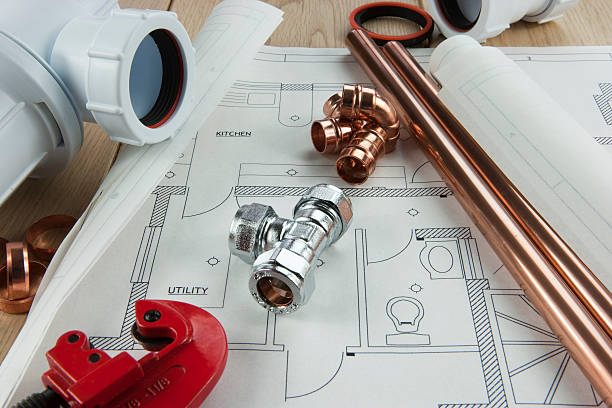

Fittings at http://www.unitrade.com.my/ are components in industries and everyday life, serving as connectors as pipes and other components . Malaysians encounter fittings in plumbing, automotive, and construction, among other fields. In this comprehensive guide, we will explore common types of fittings, their usage, advantages, and importance, providing valuable insights for Malaysians.

Understanding Fittings

Fittings are mechanical components used to connect, join, or adapt different parts of a system. They are crucial in ensuring that systems function effectively and securely. Fittings come in a wide variety of shapes, sizes, and materials to suit specific applications.

Common Types of Fittings

- Pipe Fittings:

- Usage: Pipe fittings are essential in plumbing systems. They are used to connect pipes, change directions, and control the flow of fluids.

- Advantages: Pipe fittings allow for easy installation and modification of plumbing systems, enabling efficient fluid transportation.

- Importance: Properly selected pipe fittings ensure leak-free connections, preventing costly water wastage and damage.

- Compression Fittings:

- Usage: Compression fittings are commonly found in water supply lines and gas piping. They create secure connections by compressing a ring or ferrule onto a pipe.

- Advantages: These fittings are easy to install and provide a tight, leak-resistant seal.

- Importance: In gas and water systems, compression fittings are vital for safety and preventing leaks.

- Hydraulic Fittings:

- Usage: Hydraulic fittings are used in hydraulic systems to connect hoses and pipes. They are crucial in heavy machinery, construction equipment, and automotive applications.

- Advantages: Hydraulic fittings ensure efficient transmission of hydraulic fluid and are built to withstand high pressure.

- Importance: Properly functioning hydraulic fittings are essential for the safe operation of hydraulic equipment.

- Pneumatic Fittings:

- Usage: Pneumatic fittings are utilized in air compression systems, such as those in pneumatic tools and industrial machines.

- Advantages: They provide quick and reliable connections for air hoses, ensuring efficient pneumatic system operation.

- Importance: Malfunctioning pneumatic fittings can lead to reduced productivity and equipment downtime.

- Flange Fittings:

- Usage: Flange fittings are common in industries like petrochemical, oil, and gas. They connect pipes and equipment using flanges.

- Advantages: Flange fittings offer a secure and leak-proof connection, making them suitable for high-pressure and high-temperature applications.

- Importance: In industries with stringent safety and environmental regulations, proper flange fittings are crucial for preventing leaks and accidents.

Importance of Proper Fittings

- Safety: The correct choice and installation of fittings ensure the safety of individuals and the integrity of systems, especially in industries like construction and manufacturing.

- Efficiency: Proper fittings optimize the performance of systems, reducing energy waste and operational costs.

- Durability: High-quality fittings are essential for the longevity of systems and equipment, minimizing the need for frequent replacements and maintenance.

- Environmental Impact: Leakages due to improper fittings can lead to environmental damage and resource wastage, making the selection of suitable fittings crucial.

Conclusion

In conclusion, fittings play a vital role in various industries and everyday life for Malaysians. Understanding common types of fittings, their usage, advantages, and importance is essential to ensure the safety, efficiency, and reliability of systems and equipment. Whether in plumbing, hydraulic systems, or industrial applications, the right fittings are the key to seamless operations and minimizing risks. Malaysians should prioritize proper fitting selection and installation to optimize their systems and contribute to safety and sustainability in their communities.